Winter Weather CIPP: How to Adapt Your Process for Cold Climate Success

See if this sounds familiar:

You started a simple liner install, but out of nowhere you’re finding yourself spending a couple of extra hours waiting for the resin to cure. It’s the same mix as usual, just a simple run, and no weird infiltration issues, but you still can’t get the new liner to harden.

What you’ve probably run into isn’t a liner issue or a resin issue. It’s a temperature issue.

When you aren’t prepared for colder weather, you might just find yourself stuck with a half-cured liner and a whole lot of frustration. But it doesn’t have to be that way, as long as you know what to do when temperatures drop.

TL;DR

Ambient curing in cold temperatures (below 60–65ºF) can result in longer cure times, problems with incomplete curing, and soft spots in the liner

You can adjust your cure times using different hardener formulas and adding activators

Prepare for cold conditions by having activators and hardeners in stock, as well as having temperature-specific mix charts

Cold-weather CIPP repairs are more consistent when using heat-cure or UV light systems

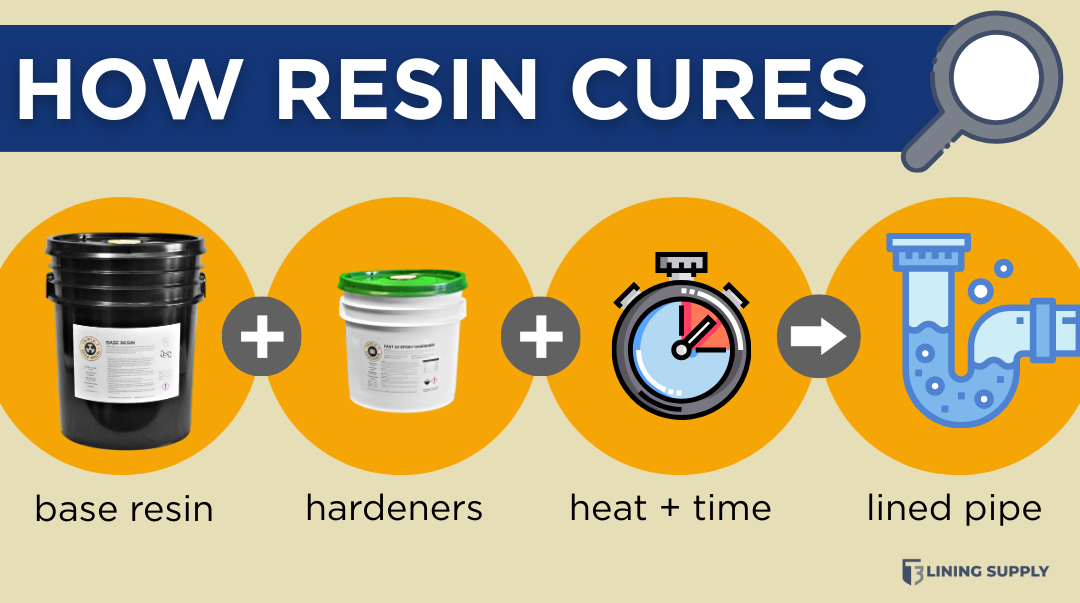

How Does Resin Cure?

Vinyl ester and epoxy resins both cure using a two-part system: a resin base and a hardener. When combined, the resin starts a chemical process that turns the liquids into solid plastic. This exothermic reaction starts the moment the two components are mixed, but it can be slowed down with cooler temperatures.

In ideal climates (77ºF), ambient curing should take around 2–4 hours. When the temperatures increase, the curing time decreases. When temperatures drop, the curing time increases. The variation in resin cure time is where installers can end up in trouble if they’re not prepared.

Chemical Reaction

The resin contains epoxy groups, and the hardener contains reactive molecules (usually amines). When mixed, the hardener opens the epoxy groups and links them together into long chains. Those chains then connect to each other, forming a tight, three-dimensional network.

As this network forms, the liquid mixture thickens, stops flowing, and becomes a solid plastic. Heat speeds the reaction, but nothing evaporates. The material is chemically transformed.

Not all resins are the same. See what makes T3 a better choice.

Hardeners

Different hardener formulas provide different curing times by increasing the reactivity of the epoxy resin mixture. A 60-minute hardener, for example, will allow the epoxy to solidify in about 60 minutes at 77ºF, whereas the 30- and 15-minute hardeners reduce that time by 50% to 75% when mixed at proper ratios.

Peroxides

When heated, a peroxide like Perkadox breaks apart into highly reactive radicals. These radicals accelerate the chemical bonding process, causing the resin system to cure faster and more uniformly, especially in thick or low-oxygen environments like pipes.

The peroxide doesn’t become part of the final plastic. It acts as a trigger, controlling when and how quickly the resin hardens rather than the structure of the cured material itself.

Weather changes take formula changes. Know the best practices for hot and cold weather curing.

Why Is Cold-Climate Curing Different?

Since the chemical reaction is heat-activated, colder climates slow the curing process. This leads to both chemical and mechanical challenges for CIPP repairs.

Chemical Processes

Heat drives the chemical reaction for epoxy curing, so low temperatures starve the reaction. Without heat, resins simply don’t cure.

Mechanical Difficulties

Colder temperatures also make it harder to saturate liners evenly, leaving potential weak or thin spots in the pipe.

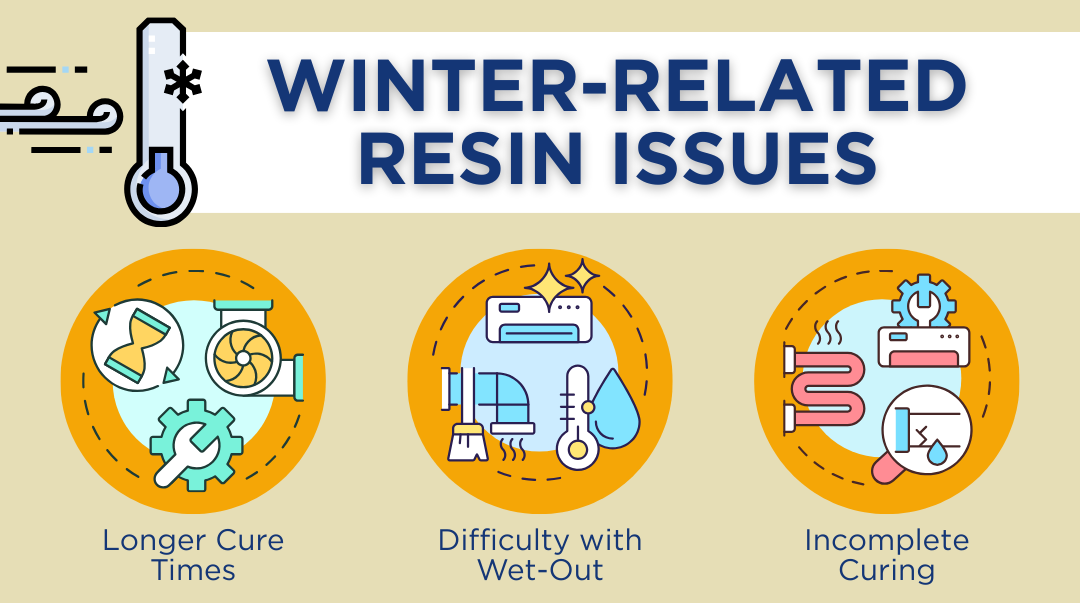

What Problems Occur When Installing CIPP Liners in Cold Climates?

Longer Cure Times

Instead of the expected 2–4 hours for ambient curing, cold-temperature curing could double that timeframe. And longer cure times mean slower working days for installers.

Difficulty with Wet-Out

Colder temperatures increase the viscosity of the epoxy mix, making it more difficult to saturate the liner evenly. When resin isn’t evenly distributed, installers end up with thin or weak spots within the liner, leading to failure.

Incomplete Curing

With colder temperatures, unadjusted resin mixtures may not cure completely, no matter how long installers wait. In these cases, the liner walls will eventually collapse, resulting in serious issues for both homeowners and CIPP repair companies.

Our 50 years of experience has shown us where you’re going to run into trouble. Prevent the biggest problems before they start with our guide.

How Do I Adjust My Resins for Cold Temperatures?

The good news is that cold temperatures don’t have to result in painful problems. The solutions differ by geographic region, but they’re simple to implement with a little preparation.

California and Warmer Climates

When your teams rely on ambient curing, especially in warmer climates like California, CIPP repair teams just need to add an activator like Perkadox or switch to a faster hardener. With the right ratios, resins will cure as expected.

T3 expert Marco Santoyo recommends a simple formula of 4 ounces of Perkadox per 5 pounds of resin to counteract seasonal changes that drop ambient temps below 77º. When the temperature drops below 65º, installers should trade out the 60-minute hardener for a 15-minute hardener.

Midwest and Colder Climates

In cooler climates, including much of the Midwest and Upper Great Plains, ambient curing is a summer-only option. While Perkadox and “hotter” hardeners can help with slightly cooler temperatures, the extreme cold in these areas requires more dramatic changes. Heat-cure processes like hot-water and steam keep curing fast and even, and UV light curing systems are even more reliable.

Want faster and more consistent cures in cold weather? UV is your best option. See how the top curing methods stack up.

How Can I Keep My CIPP Repair Teams Prepared for Cold Conditions?

There are four ways you can better prepare your teams for temperature-related issues: precalculated mixes, material availability, regular morning checks, and heating work areas.

Calculate Hardener and Activator Mixes

One of the best hacks for defeating cold-curing problems? Having all the mixes calculated for different temperatures and conditions before you ever hit the road.

Get a matrix ready with peroxide ratios, hardener replacement thresholds, and temperature-specific mix standards. This will set your teams up for success every time the temperatures drop.

Keep All Materials In Stock

Rather than panic when temperatures drop, keep all your activator and hardener reserves stocked. Teams will always be prepared, and you’ll never be surprised by a sudden change in climate.

The big guys won’t be there when your materials run out. T3 will. See what makes us your best small business partner for CIPP repairs.

Check Temperatures Before You Start

One of the most common problems Marco and the T3 team see is unexpected temperature changes. When teams leave in the morning without checking the weather, it’s the same as driving blindfolded. Set a daily protocol that involves checking working conditions against mix requirements so that incomplete curing is never an issue again.

Heat Work Areas for Colder Climates

In colder climates like the Midwest, where ambient temperatures frequently drop below 40ºF in the winter months, have a plan for heating work areas. Tarping and space heaters make it possible to improve wet-out and keep resins curing at the desired rate.

Are There Alternatives to Ambient Curing?

When ambient curing simply doesn’t work, or when you’re ready for more dependable ways to finish jobs quickly, teams can switch to heat-aided curing systems or light-activated resins.

Hot-Water Systems

Hot-water curing systems circulate heated water through the liner at a stable temperature between 160º to 180ºF. This extra heat keeps resins curing even in cold temperatures, and it can speed up the curing process by 50% or more.

Steam Systems

With temperatures as high as 210ºF, steam systems can speed curing even further with controlled heating for almost any temperature resin. The greatest advantage with steam systems is its reduced use of water, making it easier to dispose of wastewater after installation is complete.

UV Systems

The most efficient curing system for cold weather is UV light-activated resin. Instead of relying on heat activation, UV-cure resins require ultraviolet light to activate the epoxy. This shortcuts the curing process down to around 90 minutes, eliminates heat-dependent curing problems, and makes it easier to cure longer runs evenly.

T3: Your Success Partner in Any Weather

Weather shifts don’t have to sink your installations, but it helps to have the right pipe lining supply company backing you up when temperatures change. T3 Lining Supply has helped dozens of CIPP repair companies navigate tricky weather conditions, difficult installations, and training needs with top-quality equipment, materials, and support.

The Right Equipment for Your Business

With bases in California and Missouri, our experts can help any business with their toughest challenges, no matter the climate. Our California clients get advice that fits their needs, and our Midwest clients get the support they need to meet completely different challenges.

We don’t push the most expensive or complex system. We help you find the equipment and materials that work best for your location.

Support That Shows Up

Tired of automated systems when you need a real person to help you through a problem? So are we. That’s why we provide 24-hour live support with our experts, 7 days a week. No answering machines, no “press 1 for more options”, no “sorry, we can’t help you right now”. Just a real person ready to help your teams get the job done.

And did we mention we’re bilingual?

Training for Your Needs

Your training program shouldn’t be one-size-fits-all. At T3, we believe in customized training that meets your team where they need it, providing education that they can directly apply to their biggest challenges. We’ll custom design your on-site training (your place or ours) so you get the most out of every hour spent.

Ready for the T3 difference? Contact us today to get started with the best pipe lining supply company for your small business!