How CIPP Meets the Need for Environmentally Sustainable Pipe Repairs

Pipe repair has historically been hard on the environment. And with more stringent regulations, as well as a public plea for more environmentally sustainable solutions, plumbing and drain cleaning companies have started looking for alternatives. One alternative that meets, and even exceeds, the need for environmental sustainability is cured-in-place pipe lining.

The Need for Environmentally Sustainable Pipe Repairs

From carbon footprints to protective measures for delicate ecosystems, open-trench pipe replacement is no longer the preferred method for broken and damaged pipes. From small residential replacements to large-scale municipal work, conventional pipe replacement threatens the environment.

Carbon Concerns

Conventional pipe replacement is a carbon-intensive process, mostly due to the use of heavy machinery to excavate, backfill, and transport materials. With an average carbon emission of 102.1kg/meter, open-cut replacement produces large amounts of greenhouse gases.

Environmental Damage

When pipelines require repairs, there is a chance of environmental damage. Trenching can tear apart landscaping and hardscape elements, but it can also damage natural ecosystems, potentially disrupting animal and plant life.

Dismantling and replacing sewer lines could result in soil contamination. Even more concerning, industrial waste lines could create serious pollution issues.

Complex Infrastructures

Conventional pipe repair, and specifically trenching, poses a threat to the infrastructure people depend on daily. Underground power, gas, and water supply lines often cross the path of planned trenching, making it harder than ever to dig without causing collateral damage.

Whether it’s tearing apart busy roadways or damaging adjacent utilities, old digging methods are becoming less viable by the day. It’s simply not as environmentally sustainable.

How CIPP Repair Provides Environmental Sustainability

The pipe repair industry has turned to trenchless repair options to reduce environmental impact and increase sustainability. Tech like pipe bursting, pull-in-place, spray-in-place, and slip lining each provide eco-friendly benefits over open-cut methods. But one stands above the others for its simplicity, efficiency, and environmentally friendly application: CIPP, or cured-in-place pipe.

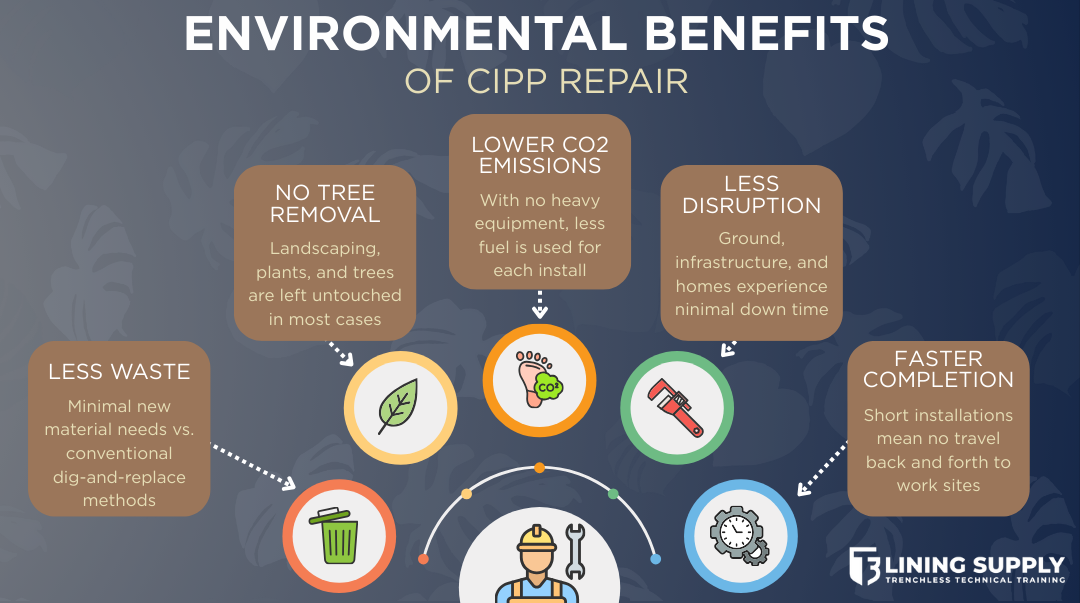

Reduced Carbon Emissions

CIPP repair does not require heavy equipment to complete, reducing the carbon emissions for each job by as much as 87% compared to conventional replacement. And since repairs can be completed in less time than conventional trenching, there’s less travel to and from the worksite and no need to transport backfill materials for rehab needs.

Minimally Invasive Repairs

CIPP lining minimizes the need for digging, making it more environmentally sustainable for pipe repair than conventional trenching. In many cases, there’s no need to dig at all. But even when digging is required, it typically takes just a small access pit to get the job done.

Both infrastructure and ecosystems can remain pristine without sacrificing the quality of the repairs.

Fewer Rehab Needs

Rehabilitation of surrounding structures, landscaping, and infrastructure features requires more resources. And that means a bigger impact on each repair’s carbon footprint. CIPP eliminates this additional environmental impact by keeping above-ground structures and features intact. This one simple solution equates to less fuel, fewer materials, and less disruption.

Less Waste

Since CIPP repair doesn’t require the removal and disposal of old materials, pipe lining also has less waste than conventional trenching and replacement work. And for techniques like UV light curing, any excess epoxy resin can be reused rather than thrown away.

Frequently Asked Questions

-

Conventional replacement requires removal of plant life, disruption to ecosystems, rehabilitation of concrete, and transport of backfill materials. CIPP repair eliminates all these carbon-heavy processes and replaces them with a simple solution that reduces CO2 emissions by as much as 89%.

-

While resin production is typically more carbon-intensive than PVC or HDPE production (accounting for around 77% of the total carbon footprint of CIPP repairs), the cradle-to-grave carbon emissions of conventional repair is far greater. Cured-in-place pipe repair reduces the average carbon output of conventional repair from 102kg/meter to around 12kg/meter.

-

With proper precautions and strict standard operating procedures, CIPP repairs pose almost no threat to plant and animal life, making it a perfect option for repairs in more eco-sensitive areas.

-

While hot water and steam curing methods are more environmentally sustainable than conventional options, UV curing reduces your carbon emissions even more by eliminating heating needs, water use, and disposal issues. UV resin also reduces or eliminates VOC and styrene emissions, providing a healthier alternative for both installers and property owners.

T3 Quality and Care: A Cut Above

The environmental sustainability of CIPP repairs depends on the materials you choose for the jobs. High-quality materials and equipment will provide better, longer-lasting, and more environmentally beneficial repairs. At T3, we take extra steps to ensure that our customers have resins and liners that stand up against the challenges of trenchless repairs.

Better Materials

All of our resins go through third-party testing measures to benchmark their durability in many applications. When you work with our T3 base resin and hardeners, you know exactly how well those resins will perform in extreme conditions, giving your customers a better experience that will hold up against years of use.

Custom-Calibrated Equipment

Our exclusive installation equipment is tailor-made to give you the best results with our resins and liners. Your teams will have better installations, more dependable results, and fewer issues in the field.

Comprehensive Training and Support

We also make sure that your team gets the repairs right every time through our above-and-beyond customer service policy. Our personalized training meets you where you are, and we’re always available when issues pop up on the work site. No other company cares for customers like we do.

Contact us today to find out what makes T3 Lining Supply different!